Manufacturing Processes

Overview

A crucial consideration in any design, the package choice lends reliability, protection, ease of heatsinking to its hybrid microcircuit. Apex has a wide variety of standard and custom package options, including metal can, power SIP, open-frame, plastic overmolds, and state-of-the-art multi-chip modules. These are made possible by our process capabilities below:

- Welded nickel caps - projection weld and seam seal

- Fine and gross leak testing

- Ceramic cavity lids

- Plastic cavity lids

- Solder dip lead finishing

- Lead forming and shear

- Lead frame fabrication

- Custom marking

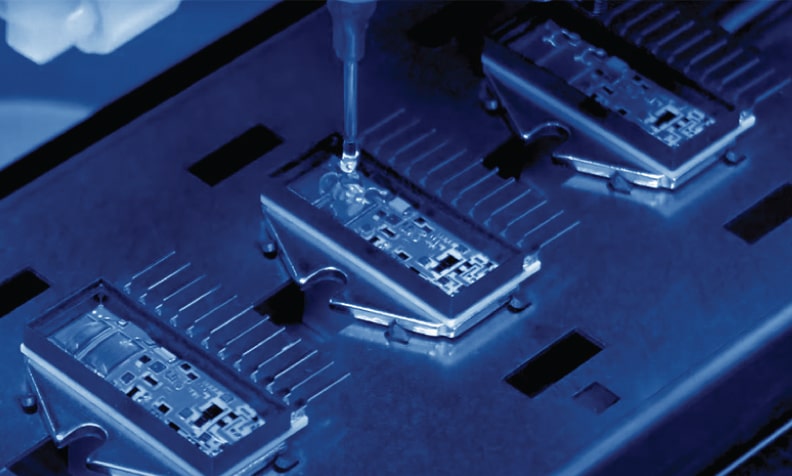

- Automated epoxy application

- Multi-chip modules

Apex excels in bringing a product to market quickly, thanks to the automation in our factory and ease of prototyping.

- Automated surface mount construction — FR4 and Insulated Metal Substrate (IMS)

- Automated bare die attach - AMB, BeO, FR4, IMS, Alumina

- Automated wire bonding - 1.25mil - 20mil wire diameter

- Laser trim — for target resistor value, target parameter, and temperature drift compensation

- Automated test equipment (ATE)

- Automated projection welder for lid attach

Military qualification tests are performed internally, including but not limited to:

- Temperature cycle: -65°C to +125°C

- Burn-in: +125°C for 160 hours

- Constant acceleration 5000G

- Temperature test 25°C, -55°C, 125°C

- Fine leak, helium leak detection

- Gross leak

As a HEICO subsidiary, Apex has expanded testing capabilities that extend beyond our in-house specialties, such as testing for our radiation tolerant produces. This includes:

- Particle Impact Noise Detection (PIND) Testing

- Single Event Effect (SEE) Testing: 37 MeV·cm²/mg (minimum), Xenon Heavy Ion

- Enhanced Low Dose Rate Sensitivity (ELDRS) Testing: Dosage – 50 krad (Si)

- High-Dose Radiation (HDR) Testing: Dosage – 50 krad (Si)

- TID Lot Traceability

In partnership with certified testing facilities, Apex can also coordinate additional radiation evaluations, including but not limited to Low Dose Rate (LDR) and Displacement Damage (DD) testing.

Our connection with HEICO strengthens our ability to meet stringent aerospace, defense, and space requirements by ensuring comprehensive testing coverage and reliability verification for all mission-critical applications.